Diesel locomotives of the series 216 would be ideally suited for operation with shuttle trains, if they had red taillights. Page 4: BR 216 (3075) provides information on how to install these.

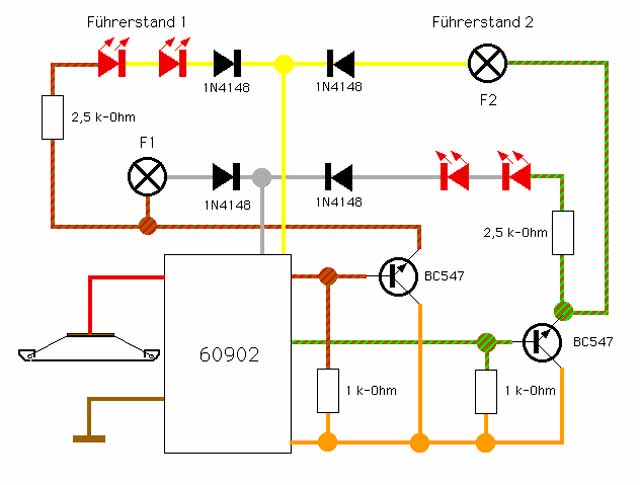

To make this locomotive's "light control" suitable for shuttle train operation I use a similar approach to switching as with the BR 221 + 60902. The only change is that the LED's require extra wires for the return. With function f1 all the lights on the side with the engineering station can be switched off, f2 does the same on the other side. As resistors I use 2.5 kilo Ohm, so the lights do not shine too brightly.

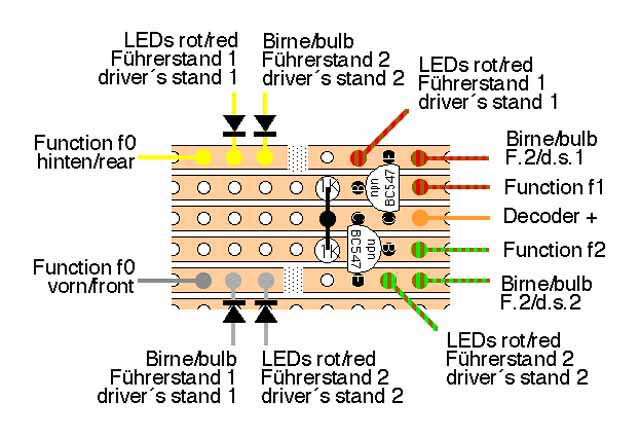

To save space I soldered everything onto a small circuit board. It is important to interrupt the conducting tracks in two places (shaded areas). Instead of the BC547's other npn-transistors in TO92 housing can be used as well, such as the BC239, BC338 or BC550. The small 1N4148 diodes will suffice but the regular 1N4001 will do as well. I mounted the 1 kilo Ohm resistors standing up. The resistors for the LED is mounted on the board as well, unlike the mounting used on the BR 216.

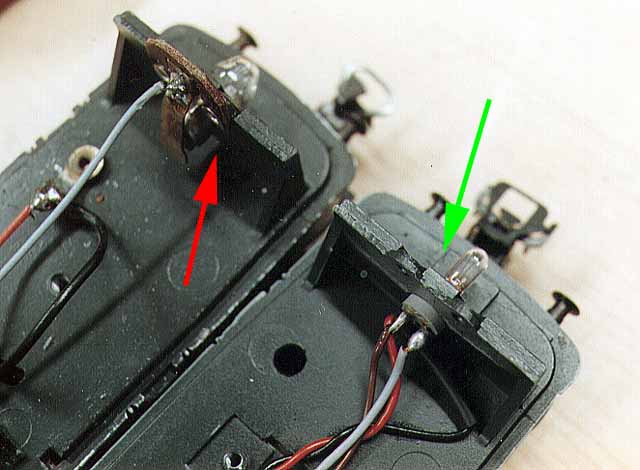

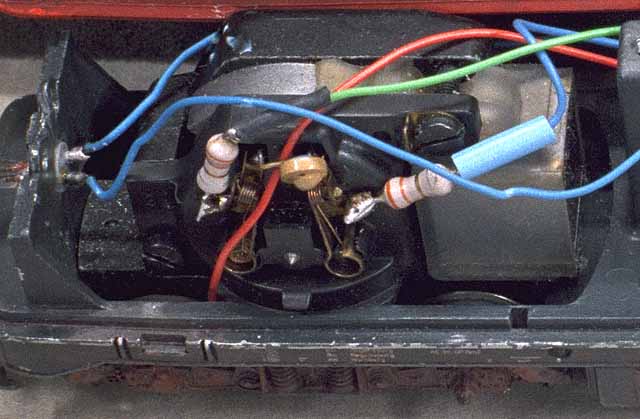

Older locomotives have bulbs 60 01 50 with appropriate sockets (red arrow). The locomotive chassis provides the ground. This type of wiring leads to ugly flickering of the illumination (see also page 15: Background). I drilled the rivets and removed the contact spring. Then I ordered Maerklin sockets 60 41 80 and pressed them in place of the old sockets (green arrow). This allows for a ground free return wire (see page 15: Solution with Diodes)and the lights are flicker-free. However since the lights should be controllable through f1/f2, the installation is somewhat different than on page 15 (consult the above diagram).

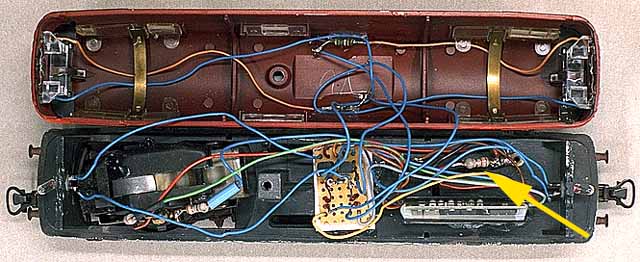

The locomotive that I modified is the old model with a LFCM. After installing an HAMO-stator 22 05 60 the motor can be connected to a c90 decoder. Aside from the two choke coils on the motor shield I added a third one (yellow arrow) between decoder and pick up shoe to protect the decoder from interference. Two of my locomotives without this coil (V200/37803 and Adenauer-01/37102) sometimes exhibited strange behavior. If I activated a special function, while they were standing still, they raced away with complete disregard for the set delay. Switching the 6021 was the only thing that helped.

I soldered the wires leading to the LED's to the circuit board in the chassis, so that the locomotive can no longer operate without the plastic housing. However it is slow enough to comfortably do maintenance. Alternatively, plug connections can be installed. When installing the housing, attention must be paid that wires do not get pinched. After the housing was screwed down, I tested the new special functions. As expected, everything worked fine and the new LED's look realistic, as can be seen on the photograph.

Running behavior was good during the first test. Since this locomotive used to have a 6090, I was able to make precise comparisons. My first impression, based on other 60901 locomotives with DCM was confirmed. The LCFM travels uphill and on the level free of any jerks at speed setting 1, downhill slight load changes can be observed. This is not the case with DCM's. I suspect the 3-pole rotor is the cause, even though this was less obvious with the old 6090. The 33722 travels clearly quieter, even though it also only has a 3-pole LCFM. As previously mentioned, this is valid for downhill stretches. The high top speed of this locomotive is a second annoyance. I calibrate all my locomotives to run at 100km/h at level ten. The 216 is unable to travel slower than 106km/h, even though the potentiometer for top speed on the 60902 is set to the minimum. Thus the tale of "the new decoders adapt better to the motor characteristics" just died. Pity.

After a 30-minute run-in period the behavior of my LCFM clearly improved. "Load change" jerking nearly disappeared. The delay is now set to 50%. After I filled the oil pockets on the motor with lubricant and greased the gears with Teflon lubricant, the motor makes less noise at level 1 than a DCM and is nearly as quiet as a Roco locomotive. It travels better than my 260 (3664) with DCM, 6090 decoder and 5-pole rotor. This supports my statement that the 5-pole rotor is not always superior. Conclusion: A 5-pole rotor is not necessary for the LCFM to obtain good running characteristics, the large rotor diameter is sufficient. The slightly increased top speed remains a disadvantage.