For a long time my E 94 279 (3722) drives reliable on my layout. It is the only locomotive with LFCM engine and a controlled, high-efficiency propulsion with 6090 decoder. The traction and driving quality is comperable with other 37xxx locos, only the engine sounds louder with the 3 pole rotor. This motor/decoder combination encouraged me to rebuild some of my locos with LFCM to 6090. The results were different. Often they were too fast, like my BR 103. Anyway I looked in second hand shops for older locos. One day I found a 3022 from 1966-1970, which was much cheaper as in the Koll catalog written. It was the E94 276 and it fits perfect to my other german crocodile E94 279. A large train behind these two locos in double heading must look pretty.

This two locos have not only a different number. The old 3022 has no sunshade roof above the front windows like the 3722, and the cooling conduit on the side is silver colored. Maerklin has in the sixties only one type of pantograph, the DBS65. This is inappropriate for an era 3 crocodile, so I mounted the SBS 10 (7202) onto the roof. I want to take the pantograph of the 3722, but it will be delivered without isolation imitations. This parts are glued onto the roof and I had no spare part number. Another solution would be the Sommerfeldt pantograph 978.

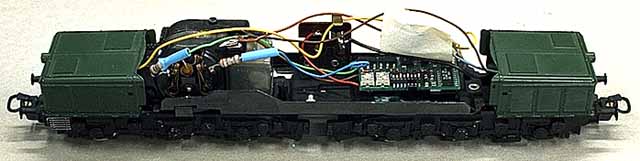

First I removed the body and srewed off the mechanical direction relais. The stripe of sheet metal looked not solid enough to fix a decoder on it. I cut off this piece and I smooth all. So I was able to glue a holding device 25 88 20 and put the decoder into it. To change the stator the hole motor must be removed. First the screw before the stator must be srewed off. After that the hole engine can be pulled to the back. Now it is easy to remove the motor shield und to install the HAMO stator 22 05 60. I use the Robbe teflon grease to lubricate the gearbox und proofed all for a well function. I pushed back the engine into the locomotive undercarriage. It was difficult to tighten the screw, because the magnet of the stator dragged the screw. Now the mechanical conversion was finished.

The decoder was already for wireing. The red wire leads to the pickup shoe and the brown one to the ground screw of the motor shield. To give the front bulb a good ground contact, there is a second soldering point. The green and the blue wire were connected with two coils to the motor shield. It was difficult to remove the body, because the coils touched the metal body inside. After a while I removed the coils and glued both near the decoder onto the undercarriage. Besides it looks better, as one can see the coils behind the driver´s window. The grey wire leads to the front bulb and the yellow one to the rear bulb. This locomotive had the old bulbs and they shines too bright on digital layouts. To correct this, I solder 80 ohm resistors before both bulbs. This old bulbs have no groundfree backwire and would be flicker. I solder my "anti flickering electronic" between. How it works is to see on page 15: solution with capicators. If there is a soft buzzing to hear, don´t worry, this is ok. To protect the electronic components I bend all with glue stripes.

Now the locomotive had to show with a test drive, that the reconstruction is well done. The loco caught the 100 km/h mark with speed level 10 and the max. speed poti of the decoder was not at the lowest point. Backward the loco was slower, it reached only 85 km/h. I think the rotor was not a precision work (take a look at Last News: October 1999). To start a heavy train uphill was the second problem. The stator has the same magnetical power as the stator of 3722, so I think there are tolerances at the 6090 decoders. Some decoders are more powerful and regulates better uphill. I had removed this decoder from a steam loco 41, and it had the same problem with the traction power. After I removed the 3 pole rotor against one from my locomotive 103, which is between rebuild to DCM, the different speeds between backward and forward were gone. Except for the less traction power, the conversion is well done.

The prototype:

E94 262 to E94 285 (194.5)

Model year 1953-54

Hourly output: 4680 kW / 6364 HP at 87.6 km/h

Top speed: 90 km/h

Weight: 123 metric tons

Length overall: 18600 mm

Axle sequence: Co´Co´

Driving wheel diameter: 1250 mm