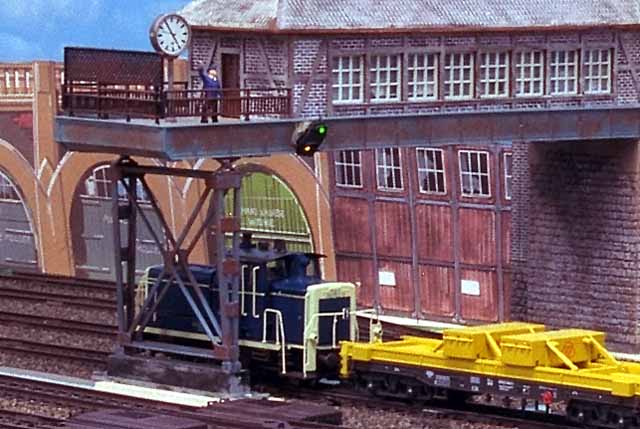

My shunting loco 260 from Maerklin had contact problems and the traction power was poor, so I was looking for an another shunter. The model from Fleischmann is older and has less details, but Roco has interesting locos. My wish was a red V60 or a blue/beige 260, but I found only a blue/beige 360. Anyway I bought this loco. I think the little different with the number is not a bad impression. Maybe Roco will produce in future a 260 in the same color, so I can change the body.

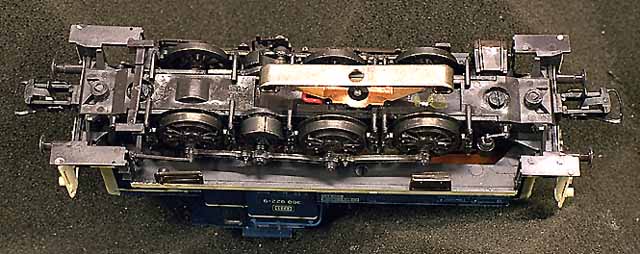

I bought the DC version, because the AC version has a reverse relais for analogous mode, and I need not this in digital mode. I want to save money. To put a pickup shoe under the loco is no problem. My other DC locos runs on my K track without delailings, so I don´t see any problems to use this loco. The AC version of the 360 has two traction tires, but the DC version has none. So there are two wheels more for the electrical contact. The loco is very heavy (245g), so I expected no traction problems. Two axles are well sprung und has always a good contact to the rails. The 260 from Maerklin has only a weight of 180g and all axles were fix in the undercarriage. This shunter has often poor pulling power with its one traction tire and contact problems.

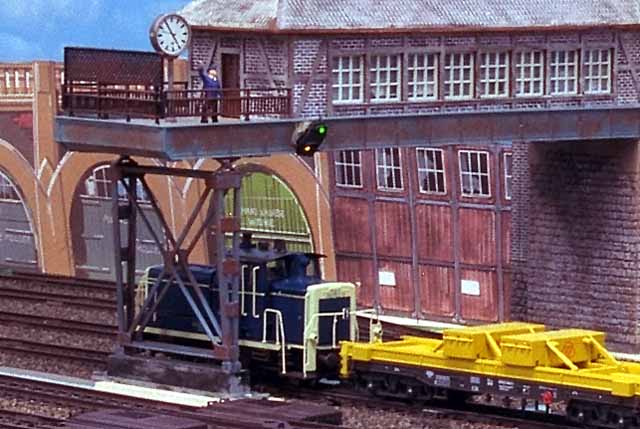

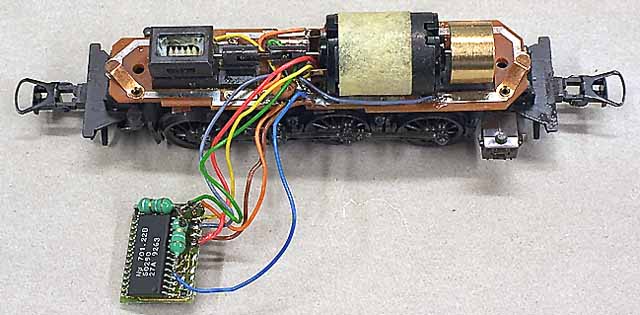

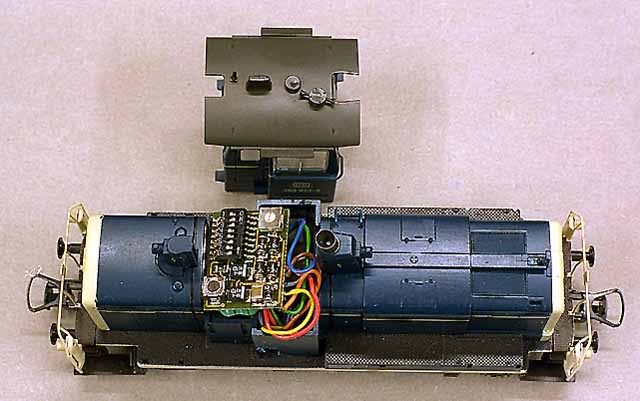

First I dismantled the loco. The two screws near the couplers under the loco must be unscrewed. After this the body and the ballast weight can be removed. Under the body is a small motor which drives the axle C with a worm. The other wheels are driven by the coupling rods. Under the gangplank is a small circuit board, which must be modified. To got the circuit board, the motor must be removed. In the middle under the loco is a long screw, which fix the motor. After uncrewing it, the motor and the shaft to the worm can be removed. It was a little difficult to remove the circuit board, because it jammed at the worm box. I got it after a while and then I enlarged the hole in the circuit board a little (blue arrow).

In DC systems the light changing is controlled by two diodes, and this must be modified for the digital use. I cut two circuits on the board (red arrows) from the bulbs to the wheel contacts and removed the diodes. In opposite to the DC sytems, the Maerklin system has at both rails ground power. This is the reason why I connect the wheel contact of both sides together. I done it with a little wire on the bottom side of the circuit board. To avoid shortcuts, I glued a piece of paper between the board and the undercarriage.

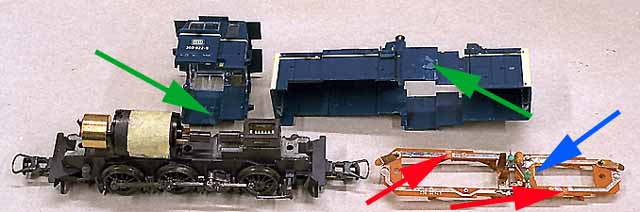

All my other locos from Roco uses the 60902, but it is too large for this little shunter. The steam loco 086 from the train set 26508 has a special decoder, which has the half size of the 60902, but no functions f1 and f2. It is possible to buy this decoder with the number 60 38 58. It fits perfecty into the driver´s stand. For a easy adjusting, I was looking for a solution to remove the roof which one touch. It works, if the "plastic noses" were grinded off (green arrows).

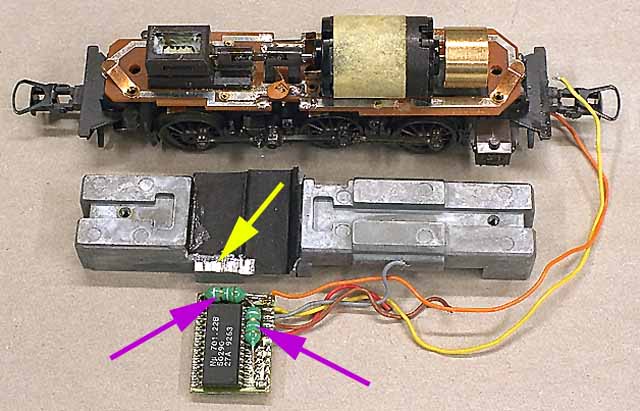

I left the capicator at the motor untouched. I soldered off one pin of each coil to connect them later to the blue and green wire of the decoder, but now the ballast weight will not fit. I removed both coils and solderd them directly onto the decoder(purple arrows). To fit the decoder peferctly into the driver´s stand, a part of the ballst weight must be removed with a Dremel and a tungsten carbide cutter(yellow arrow). At last a glued a black piece of paper onto the ballst weight to avoid shortcuts.

Now I connected all wires from the decoder with the loco. The bulbs shines very bright and who´s cares had to add a 100 ohm resitor to the orange wire. The decoder works very good with the motor. At the lowest speedlevel the motor runs without jerking and the regulation works perfect. Impressing is the low noise of the motor. By comparison the V60 from Maerklin kick up a row.

The assembly was quite easy. First the ballst weight was put on the motor and the wires were laid at the side through the hole. After it, the gangplank can be put on the loco and the decoder must into the hole of the body to the driver´s stand. At last the decoder can be pasted with a little glue. So it is easy to adjust the loco without removing it from the track. After the adjusting work, the middle part of the body can be put on.

I bought the DC model without a pickup shoe, but it is easy to put one under the loco. I paste the Roco 40003 with some glue into the ready made hole. At last a wire must be soldred to the pickup shoe.

Now came the test drives to adjust the loco. The loco has a good gear ratio. If the screw for max speed is set to max., the speed is 80 km/h at speed level 10. Normally all my locos are set to 100 km/h at speed level 10. So I do a trick. I set the loco to 70 km/h at speed level 14, and set the max. speed level to 12 at the computer. So it runs not faster than 60 km/h, like the original. Then I changed my computer program, so that this loco reacts like my other locos.

Most impressing is the low noise of this loco. Also there are nearly no contact problems, by comparison with the V60 from Maerklin. One reason is the small pickup shoe with its high pressure, the second reason are the well sprunged axles. Additional the DC version has no traction tires, so all 6 wheel can be used for electrical contact. Without tires the loco has less pulling power, depite the weight is much higer. It is enough to pull some freight cars, but passenger cars with pickup shoes are a real problem on turnouts. In this case, my old V60 with one tire was not better. The AC version from Roco has two tires and much more traction power.